- Ruhr-Universität Bochum

Research Projects

Collaborative Research Centers

- SFB 1625: Atomic-scale understanding and design of multifunctional surfaces.Compositionally complex solid solutions (CCSS) comprising five or more different elements mixed in a simple single-phase crystal structure provide conceptually unique, highly promising prospects in important scientific and technological areas, where the surface dominates properties such as – and ultimately not limited to –electrocatalysis and corrosion, crucial for future sustainable energy conversion systems. The CRC aims to leverage the possibilities of CCSS as material design platforms by establishing a combined theoretical and experimental understanding of their atomic-scale surface features, as the unique properties of CCSS are caused by the large number of diverse poly-elemental active sites across their surface. Gaining control of and the ability to design these surface atom arrangements (SAA) has the potential to overcome limitations of conventional electrocatalysts and will pave the way to multifunctional materials, with unprecedented combinations of activity and stability as well as possibilities for cascade reactions. SAA are specific arrangements of (sub)surface atoms and their chemical identities. They form in statistical abundance the surface composition of CCSS. Knowledge of SAA is essential for designing composition-structure‑activity relations for CCSS surfaces. The CRC aims to understand and control SAA – their formation, their variation for different systems and compositions, changes in SAA due to experimental conditions – to systematically tailor and manipulate them to design their properties. Development of new catalysts is not the primary goal; rather, advancement in fundamental understanding and exploration of new opportunities offered by SAA of CCSS. Initially, noble metal thin films will be used as model CCSS as their oxidation resistance supports SAA identification. Gaining detailed insights into the dependence of reaction mechanisms on the SAA and the understanding of CCSS surface metallurgy will then enable the design of multifunctional and sustainable electrocatalysts. This multi-dimensional challenge will be addressed by a fully interdisciplinary team (materials science, surface science, physics, chemistry, data science) using high-throughput methods in atomistic simulation, synthesis, characterisation, electrochemical probing, and in-depth experiments towards atomic-scale resolution. SAA determine electrochemical reactions on the atomic scale which is addressed by theory and atomic-scale characterisation. However, this atomistic view needs to be combined with the high-dimensional composition-property space of SAA and CCSS. Using materials informatics, we will integrate all data across scales and research areas, establish data-guided workflows, extract knowledge from data and organise it in knowledge graphs. Our holistic approach will be used to fulfil the vision of the CRC to control SAA on the atomic scale and across the surface and enable the design of ideal CCSS surfaces for specific applications.

- TRR 103: From Atoms to Turbine Blades – Scientific Framework for a New Generation of Single-Crystal Superalloys.

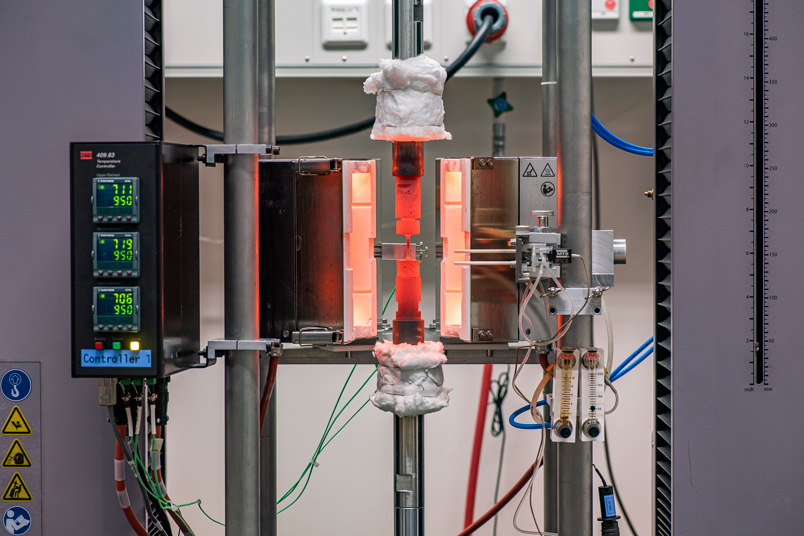

Turbine blades in gas turbines are as indispensable for keeping modern society moving as they are for providing a steady, sustainable supply of electricity. Aside from their use in energy production, gas turbines are also employed in aviation. The key materials for these turbine blades are so-called monocrystalline superalloys – alloys based on nickel.

In order to achieve both a higher degree of efficiency and greater sustainability with these superalloys, the collaborative research centre project SFB/Transregio 103 “From atom to turbine blade – scientific foundations for a new generation of monocrystalline superalloys” is investigating completely novel monocrystalline technologies.

Fundamental questions lie at centre of the research – for example, questions concerning which structural formation processes occur during the production of components, and whether the application of high temperatures will cause microstructures to disintegrate (degradation). SFB/TR 103 brings together researchers from the fields of materials science and engineering, solid state physics and chemistry, and cross-scale material modelling and production engineering.

SFB/TR 103 is based at RUB (coordinating institution) and at the University of Erlangen-Nürnberg. The German Aerospace Centre (Deutsches Zentrum für Luft- und Raumfahrt – DLR), the Helmholtz Research Centre Jülich, and the Max Planck Institute for Iron Research are participating in the project as well.

- SFB 247: Heterogeneous Oxidation Catalysis in the Liquid Phase – Mechanisms and Materials in Thermal, Electro-, and Photocatalysis.

The CRC/TRR 247 aims at bringing heterogeneous oxidation catalysis in the liquid phase to a level of fundamental understanding that is comparable to metal catalysis in the gas phase, i.e. to unravel the nature of the catalytically active sites and the reaction mechanisms. The research programme is built on three working hypotheses:

- The structural prerequisites relevant for efficient oxidation catalysts (active site precursor motifs) can be identified by experimental correlations of structural features beyond the ideal crystal structure with catalytic activity.

- Theory together with thorough in situ and operando analysis of these features will enable to clarify the nature and evolution of the working active sites.

- A systematic comparison of the same catalyst in a selection of different oxidation reactions of hierarchical complexity and using thermal, electro-, and photocatalysis will deliver trends, from which the generic catalytic functions and – in close collaboration between theory and experiment – the relevant elementary steps and the full reaction mechanism can be deduced.

The central collaborative element of the CRC/TRR 247 will be a Comparative Study that is designed to verify these hypotheses. The materials basis is comprised of mixed cobalt-iron oxides of the spinel and perovskite type, which are active and suitable prototype materials for the elaboration of composition- and structure-activity correlations. The reactions under study are selective oxidations of alcohols, saturated hydrocarbons, olefins and the redox chemistry of dioxygen.

The first funding period will be devoted to the establishment of experimental structure–activity correlations and theoretical modelling of the active site candidates. In the second funding period, we will converge theory and experiment and address the reaction mechanisms. Additionally, we will start to generalize the results to other oxide catalysts. In the third funding period, the generated knowledge will be employed for the rational design of superior new metal oxide catalysts for innovative liquid-phase catalytic processes.

- SFB 1316: Transient Atmospheric Plasmas - From Plasmas to Liquids to Solids.

Non-equilibrium processes are the basis of a multitude of phenomena in nature such as transport, excitation of atoms and molecules and de-excitation and dissipation at surfaces. The non-equilibrium character of plasmas is especially pronounced due to the high energy density in these systems and the very selective excitation of, for example, only the electrons. If these plasmas are brought into contact with solids or liquids, the non-equilibrium character can be transferred to other states of matter. An excellent example are plasma chemistry processes that are directly coupled to catalytically active surfaces.

The use of non-equilibrium atmospheric pressure plasmas is most interesting since they can most easily be combined with standard chemical processes. The non-equilibrium character of these plasmas can be controlled by large gas flows or by short pulsed excitation assuring strong cooling mechanisms. Thereby, a huge variety of desired plasma chemistries or emission patterns can be adjusted following an empirical strategy. However, any further progress is hampered by the lack of a fundamental understanding of those discharges and their interaction with fluid and solid interfaces leading to many open questions:

- How to reach and maintain a stable atmospheric pressure non-equilibrium discharge in a range of different gas mixtures?

- How to efficiently transport the species from the plasma to the object to be treated or coated? What are the chemical non-equilibrium synthesis routes of new materials or species?

- How does the transfer of species and energy occur on the nanosecond timescale?

- What are the roles of gaseous, liquid, biological, and solid state catalysts in contact with those plasmas?

- TRR 196: Mobile Material Characterisation and Localisation by Electromagnetic Sensing. concluded

The aim of the CRC/Transregio is to trial new approaches to mobile material detectors. This would enable the material properties of any object to be determined, even if it were concealed behind a wall, making it possible to locate unconscious persons in a building filled with smoke or contaminated with poisonous gases, or to detect burning cables inside walls, for example. To achieve this it is necessary to develop mobile detectors that record data in a frequency range from several gigahertz to terahertz, which can be used to precisely localise and characterise a complex environment.

- SFB 837: Interaction Modelling in Mechanised Tunnelling. concluded

Mechanised tunnelling is an established flexible and efficient technology for the construction of underground infrastructure, characterised by a dynamic advancement of tunnel boring technologies, increasing TBM diameters and a broadening range of applicability. This rapid development in association with the inherent heterogeneity of the underground and the uncertainty of ground parameters, poses new challenges to reliable prognosis models. Such models are indispensible for the limitation of tunnelling risks in the design and construction phases, particularly if difficult conditions in terms of geology or tunnelling have to be considered.

Considering this background, the subject of the Collaborative Research Centre is the research and development of models, methods and design concepts, which, when adequately interlinked, can deal with the manifold complex interactions of the components (ground, shield machine, support measures, tunnel lining, existing buildings) and processes (advancing and excavation process, construction operation) involved in mechanised tunnelling. The goal of the Collaborative Research Centre is to enable more efficient, low risk and environmentally friendly solutions in the design and construction of shield supported tunnels.

The four project areas of the Collaborative Research Centre will consider all essential components and processes involved in the design and in the construction phase. This includes the ground exploration and ground modelling, the tunnel boring machine, the lining systems, the various supporting measures and the effects of tunnelling on existing structures. Furthermore, the cutting and advancement processes will be represented by adequate models integrated by means of a consistent Collaborative Research Centre wide information management system.

- TRR 87: Pulsed High Power Plasmas for the Synthesis of Nanostructural Functional Layers. concluded

The path to new materials, e.g. for storage media for cell phones, PCs, but also for future energy systems, goes via plasma technology. Electrical and information engineers, physicists and also mechanical engineers from the "Plasmas with Complex Interactions" Research Department in Bochum are researching fundamental questions of plasma physics from the atom in the gaseous phase down to performance characteristics of coated material surfaces with scientists at the Technical University Aachen (RWTH).

Although plasma coating of surfaces is already being used industrially, the development of new surface coatings is mainly empirical, as there are no scientific foundations on the interactions of plasmas with surfaces. The researchers intend to close this gap on the basis of examples. Their object of research on the one hand is machine components equipped with anti-adhesive and wear-resistant coatings, on the other hand expandable barrier layers on thermoplastics.

The central subject in Bochum is pulsed plasmas, partly with magnetic field support, as they are important for the forward-pointing synthesis of intelligent coating systems. Parallel to this, the coating systems developed are qualified and prepared for large-scale technical application in the area of Material Research at the RWTH Aachen.

BMBF

- ForMikro FlexTMDSense - Research into novel, flexible sensor systems based on two-dimensional material systems. concluded

In the BMBF-funded ForMikro project FlexTMDSense - "Research into novel, flexible sensor systems based on two-dimensional material systems"ultra-thin pH and gas sensor systems based on two-dimensional (2D) semiconductor films made from the transition metal dichalcogenide material class are being researched. The 2D electronics/sensors are transparent, flexible and biocompatible. Yet the technology for this cutting-edge field of microelectronics - based on 2D materials - does not yet have the maturity necessary for industrial mass applications. In the FlexTMDSense project, an innovative, monolayer accurate deposition and ablation technology at low temperatures for the fabrication of low-cost, flexible, ultrasensitive, electronic gas and pH sensors will be elaborated and subsequently fabricated on an industrial scale in an 8-inch cluster facility. Novel precursors are synthesized and large area films are grown with monolayer precision using atomic layer deposition (ALD). The low process temperatures enable a scalable bottom-up approach on flexible substrates while maintaining a high surface-to-volume ratio. The lightweight and flexible design of the sensors makes them particularly suitable for use in the healthcare sector and for smart packaging. Due to the low-cost and resource-saving approach, a high broad efficacy in a wide variety of application areas, e.g. health monitoring or wearables, can be expected.

International Max Planck Research School

- International Max Planck Research School on Reactive Structure Analysis for Chemical Reactions (IMPRS RECHARGE).

The training of young academics is essential for the future of science and research. Therefore the Max Planck Society launched a unique postgraduate training program – the International Max Planck Research Schools (IMPRS).

In a highly competitive process the Max-Planck-Institut für Chemische Energiekonversion (MPI CEC) was able to secure funding to establish a new IMPRS. Together with Ruhr-Universität Bochum, Universität Duisburg-Essen, Universität Bonn and the neighboring Max-Planck-Institut für Kohlenforschung the IMPRS on Reactive Structure Analysis for Chemical Reactions (RECHARGE) was founded. Spokesperson for the Research School is Prof. Dr. Frank Neese, Director at MPI CEC.

IMPRS RECHARGE focuses on interdisciplinary research between chemistry and physics with an emphasis on catalytic mechanisms, physical-chemical analysis and energy topics. Scientific challenges shall be looked at from different angles. Furthermore the combination of theory and practice is a vital aim of the IMPRS RECHARGE.

- International Max Planck Research School for Interface Controlled Materials for Energy Conversion (IMPRS SURMAT).

The International Max Planck Research School for Surface and Interface Engineering in Advanced Materials (IMPRS-SurMat) is a structured three-year doctoral programme that gives outstanding students from Germany and abroad the possibility to pursue a PhD. It provides a unique combination of excellent research conditions plus an intensive and interdisciplinary teaching program. The working language is English.

The research focuses on questions centered on surfaces and interfaces of advanced materials. In this context all projects within the IMPRS-SurMat are interdisciplinary - chemists, physicists, material scientists and engineers work together and the approach to the research topics can be experimental as well as theoretical by modelling and simulation.

The school is a cooperative effort from two Max Planck Institutes and one university all located in North Rhine-Westphalia in the west of Germany.

After the successful completion the doctoral degree is conferred by the partner university. In addition the graduates receive a certificate by the IMPRS-SurMat.

Research Building

- Center for Interface-Dominated High Performance Materials (ZGH).

Whether turbine blades for airplanes or for power generation, electrical/hybrid drives or fuel cells and catalytic reactors – a long lifetime in harsh environments such as high pressure, high temperature, and aggressive surroundings is the main requirement of high-performance materials. These materials exhibit high structural integrity and simultaneous multifunctionality. The interfaces of these materials can improve the mechanical properties and create new chemical and/or electronic functions. In ZGH, metallic, semiconducting and dielectric materials will be investigated with a focus on the scientific understanding and design of interfaces. Mechanically, chemically and physically dominated high-performance materials will be developed by fundamental understanding and control of interfaces on the atomic scale. Results will be transferred to macroscopic materials. The researchers will design novel materials with new combinations of structure and functions. An intensive interdisciplinary collaboration in the fields modeling, synthesis, processing and characterization of materials is needed.

ZGH will house the latest methods for materials characterization such as aberration-corrected transmission electron microscopy and a three-dimensional atom probe. These tools allow a basic understanding of the atomic structure of materials and the systematic development of new materials. The close combination of scale-bridging experiments and simulation on atomic, microscopic and macroscopic scales characterizes the scientific program of the ZGH.